Personal project "HushSnap"- UV, privacy and sound blocking clip-on shield

This project started with my own apartment: too hot in the summer, too loud year-round, and no privacy. I set out to design a renter-friendly shield that finally fixes all three.

I’m currently prototyping this clip-on UV and privacy shield, and I want to use it as a way to dip my feet into building a startup. The plan is to start producing small batches and properly validating the idea as a real company while I’m on exchange in Singapore.

The problem

When I moved into my current apartment, I ran into three problems at once:

- Overheating - large windows, no AC, and a room that turns into a greenhouse in summer.

- Outside noise - buses and traffic cutting straight through the glass.

- Privacy - all throughout the day, my windows basically turn into a display case.

The usual fixes weren’t a great fit:

- The room doesn't have a spot for curtains; therefore, blackout curtains aren't feasible.

- Adhesive window films aren't allowed for double-pane glass, since they can heat the outer pane more than the inner one and increase the risk of cracking.

- Permanent installations (screws, frames, caulking) are off-limits under the current lease.

So I set myself a design challenge:

Create something that makes the room cooler, quieter, and more private, clips on and off the window, and leaves no trace in a rental.

That became the starting point for a HushSnap: a removable clip-on shield that sits in front of the glass, blocks UV, improves privacy, and helps with noise - without permanently damaging the window.

Possible designs

I considered two attachment methods:

- Suction cups + magnets (current prototype)

- Spring-loaded frame + magnets (future design better suited for noise isolation)

Suction cup design

The suction-cup design is the version I’ve taken the furthest and actually modelled as a prototype.

This design uses three main components:

- Suction cups that attach to the glass

- 3D printed coupling that attaches to the suction cups and magnets

- 3D printed part that couples the UV film and magnets

The big advantages of this design are:

- Few components, which in turn reduces cost and complexity

- Makes it safer to use reflective materials near double-pane windows by introducing an air gap

- Leaves the window itself untouched and easy to restore

The “sheet” can be swapped depending on priority:

- Reflective film for UV, privacy and heat reduction

- Layered film, if I want to experiment further with a focus on noise reduction

What this solves in my apartment

- Privacy: the shield acts like a one-way mirror for the window - people outside see a reflection or tint instead of a clear view in.

- Heat & UV: By reflecting part of the solar load, the room doesn’t heat up as quickly on hot days.

- Renter-friendliness: everything is held by suction cups and magnets. No drilling, no adhesive, no permanent marks.

Noise reduction in this configuration is limited but non-zero. You get a small benefit from the extra layer and air gap, but it’s not a full acoustic window insert-and I’m comfortable with that trade-off for the first iteration.

Spring-loaded frame design

The second attachment method I explored on paper uses springs instead of suction cups.

In this version, slim spring arms push out into the window frame and hold the same kind of shield (film or layered panel) in place. The goals of that direction:

- Make the mount feel mechanically solid for users who don’t fully trust suction cups over time

- Allow for thicker, more noise-focused layers (foam or multi-layer film) while still keeping the air gap

- Stay fully renter-safe - no screws, no adhesive, and no added hardware on the actual window frame

Right now, the spring-loaded idea lives as a conceptual “version 2” for more serious noise reduction. For this first round, I decided to prioritize the suction-cup prototype, since it hits a good balance of manufacturability, simplicity, and renter-friendliness.

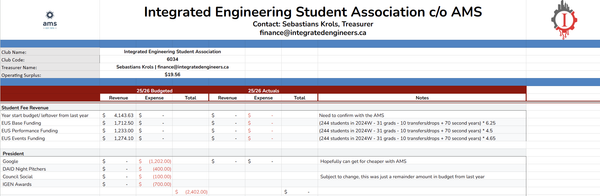

Highlights from COMR 280

I actually started this idea before taking COMR 280, but when the course project came around, it felt like the perfect excuse to go deeper. COMR 280 is an introduction to entrepreneurship with a term-long project, and I chose this UV/privacy shield as my focus. Using it for the class forced me to treat it like a real product: talking to users, sizing the market, and building out a basic business model and brand - rather than just leaving it as just a personal project.

Assignment 1 - Initial concept and personal use case

I defined the project as reflective UV-blocking window panels aimed at people in dense housing who want more privacy - starting with my own apartment.

I outlined the core benefits (privacy, UV reduction, lower heating/cooling loads) and noted my own strengths in 3D printing, CAD modelling, and access to an engineering network as key enablers for rapid prototyping and feedback.

Assignment 2 - Interview questions and early user insights

I created a structured interview guide focusing on living situation, privacy, heat, noise, willingness to pay, setup time, and preferences for removable vs permanent solutions.

Interviews with renters in UBC housing confirmed:

- Noise is often the main pain point, even more than heat or privacy

- People want removable, landlord-safe solutions with setup time under 10 minutes

- Explaining the idea upfront biases responses - I learned to let people describe their problems first

Assignment 3 - Exploring two mounting options

Here, I formally developed the two mounting methods:

- Suction-cup + rod system - uses suction cups, rods, and a reflective sheet; creates an air gap; easy to remove and renter-friendly.

- Spring-loaded frame - uses springs and foam to press into the window frame; better compatibility with different window sizes; aimed more at noise reduction while preserving the air gap.

This assignment was where the “one shield, multiple mounts” idea really crystallised.

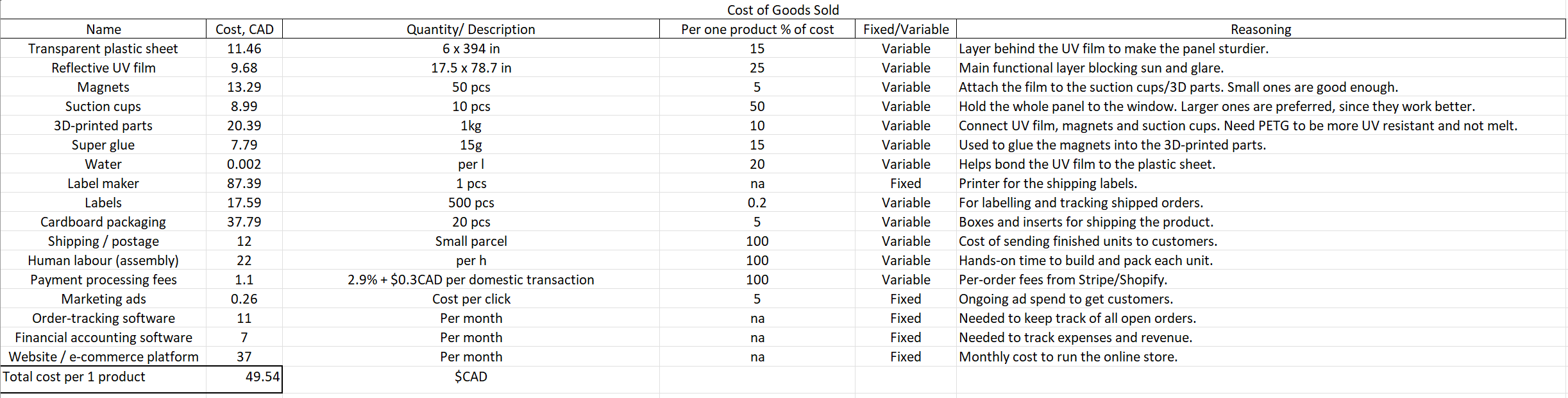

Assignment 4 - Market size estimates

I placed the product in the secondary glazing / interior window insert space and pulled rough numbers for market size:

- Global TAM: ~US$1.2B secondary glazing market

- Canadian SAM: ~US$6.41M based on population and spending

- Serviceable obtainable market (SOM): around 650 units/year in the UBC/Vancouver renter niche, assuming I can make 10–15 units per week and sell at a median price of $75 CAD per unit, leading to roughly $32.5k in potential annual revenue.

Assignment 5 - In-depth stakeholder interviews

I conducted more detailed interviews with renters like Samantha and Krishaant:

- Noise came up as the biggest issue (“every day, all through the day” / “2–3 times a week”)

- Standard metal blinds were described as flimsy, noisy, and ineffective for both light and sound

- For anything DIY, 10 minutes of setup time was the upper limit before people would give up

- Willingness to pay for a full window solution sat roughly in the $30–$75+ range, depending on how effective it was

These conversations are what pushed me to keep both mounts in mind: suction cups for simplicity, springs as a potential path for more serious noise performance.

Assignment 6 - Customer personas

I built three detailed personas - a young professional in Kitsilano, a retired couple in Victoria, and a music producer in Seattle - to stress-test whether the product made sense beyond student housing.

Common themes across these personas:

- They value quiet, privacy, and comfort in small or shared spaces

- They prefer reversible, tool-free upgrades that they can install themselves and take with them when they move

- They resonate with brands like IKEA, 3M Command, and Honeywell Home, which are known for renter-friendly, practical solutions

Assignment 7 - Business Model Canvas

I then mapped out the business side:

- Key partners: film and foam suppliers, suction cup/spring manufacturers, 3D print farms, couriers, and online platforms (e.g., Shopify, ad networks).

- Key resources: a small workspace, access to 3D printing, basic tools, and simple finance tracking software.

- Value proposition: outside noise reduction as the primary promise, plus privacy, UV reduction, non-permanent installation, and fast setup.

- Customer segments: students in dense dorms, renters near busy streets, and eventually anyone who wants more peace without modifying their windows permanently.

Assignment 8 - Product branding

For branding, I named the concept HushSnap:

- “Hush” for quiet

- “Snap” for the satisfying clip-on motion

The slogan I landed on was:

“Bringing silence in one quick motion.”

I created two visual directions with:

- Logo ideas combining window, sun, and shield elements

- Color palettes ranging from calm, neutral apartment tones to bolder, more attention-grabbing schemes

- Futuristic but readable typefaces

- Sample graphics showing sound waves and sun rays being blocked by the shield

Assignment 9 - Reflection and exploring pivoting option

In the final reflection, I reframed the project as:

A removable privacy and noise filter for renters, with UV and heat reduction as additional benefits.

I also:

- Expanded the potential customer base to include offices and corporate spaces

- Recognized a new strength: my experience managing budgets and financial projections, which will matter if this ever becomes a real venture

- Left the course more confident in the demand, but also more aware of the technical challenge in building a slim, clear, renter-safe shield that genuinely performs on noise

Right now, the project sits at a good intersection of personal frustration solved, validated demand, and clear next steps: refine and test the suction-cup shield, while keeping the spring-loaded mount on the roadmap for a future, more acoustic-focused version.