IGEN 3D Print Shop - Interviews and how to motivate a team

From joke questions in interviews to design competitions that pull everyone in.

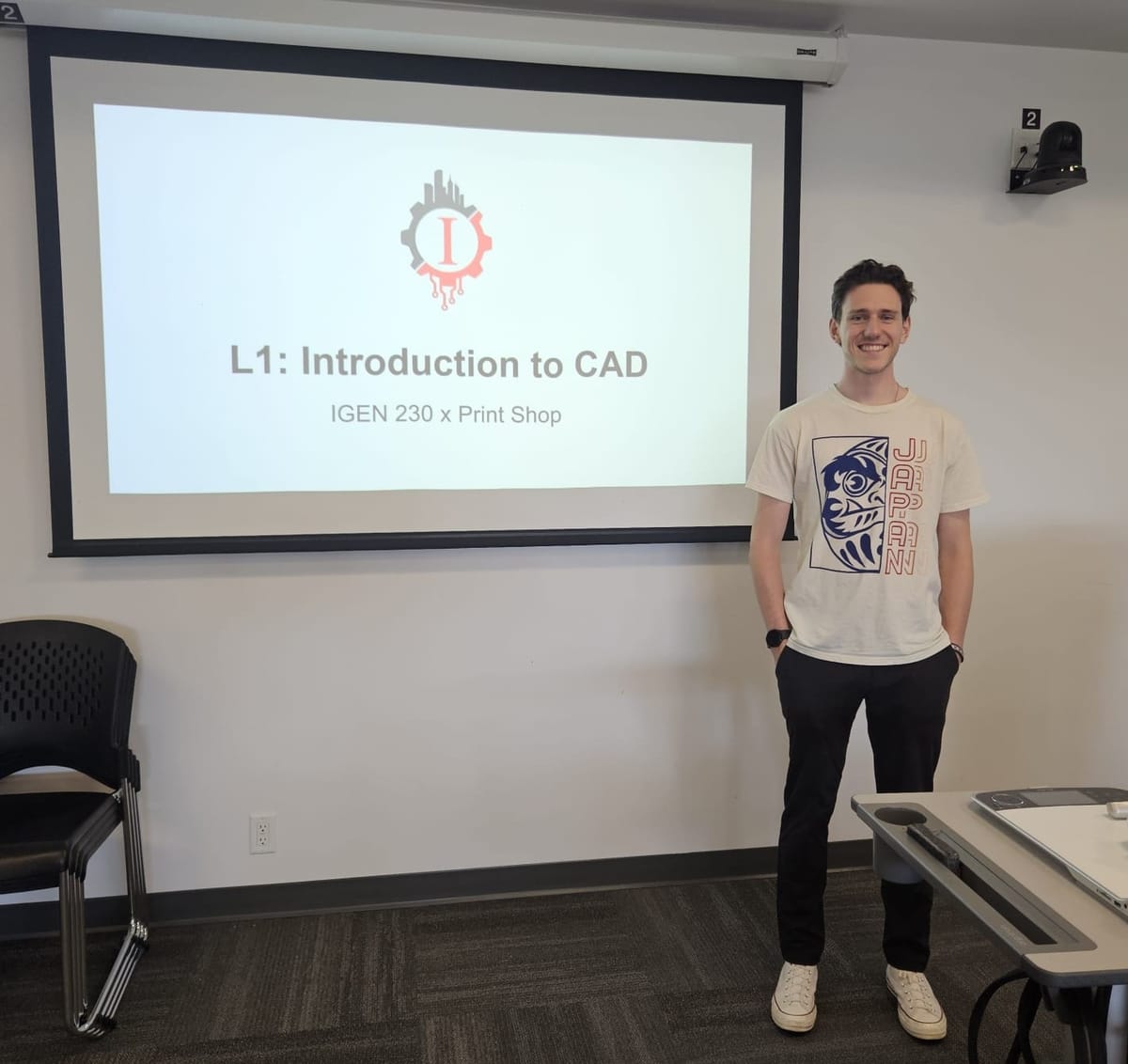

My speciality at the print shop

Since joining the IGEN 3D Print Shop last year, I’ve naturally taken on the more technical projects. One of the key upgrades I worked on was converting our RatRig from the standard configuration to a CAN bus setup. This reduced stress on the print head and eliminated cable sag, which improved reliability and print quality.

Beyond that, I handle many of the configuration and calibration tasks: generating and updating heightmaps, adjusting tolerances, and keeping the printers well-maintained. My next major project is transitioning our current OctoPrint workflow to PrusaConnect. This should make it much easier to monitor all printers at once and receive timely notifications when prints fail, instead of discovering issues hours later.

Running interviews and what I learned

Over the summer, I was one of two people responsible for running the hiring interviews for our two paid positions at the print shop. These interviews were conducted online by me and Viktor Moreno, the previous manager. Between candidates, we alternated roles so that sometimes I focused on technical questions while he covered more personal ones, and sometimes we swapped.

In September, I also led the second-round interviews for our incoming 2nd-year applicants. A clear pattern emerged: the best candidates combined solid technical knowledge with strong interpersonal skills. One of our standard questions was, “What is your best joke?” Surprisingly, this was often the most difficult part of the interview for many people. Because the role involves working with a wide range of students and staff, being able to communicate clearly and connect with others is just as important as being able to troubleshoot a failed print.

From an interviewer’s perspective, I noticed that asking more questions and taking careful notes consistently leads to better decisions. The more detail you have, the easier it is to differentiate between candidates later on. The most important insight, however, was how critical initiative is. When someone says they are passionate about 3D printing but has never taken any steps to explore it on their own, that enthusiasm feels shallow. Genuine passion usually shows up in side projects, self-learning, or at least some curiosity-driven experimentation.

How I think about motivating a team

Being part of the print shop team has given me a front-row seat to how motivation actually works day-to-day. I’ve learned that people do their best work when they’re encouraged to pursue the areas they care about and then share what they learn with the rest of the team.

For example, one teammate wanted to focus more on safety. That interest turned into a project to design and build an enclosure and ventilation system for our resin printers. The result: better safety for everyone and a teammate who felt more invested in the space.

One of the initiatives I’m most proud of is introducing a bi-monthly design competition. The idea is to challenge everyone to push both the printers and their own skills to the limit while learning something new along the way. The concept came from watching assembly-line style 3D printers that use modified G-code to push finished prints off the bed automatically. I wanted to bring that kind of experimentation mindset into our shop.

The competition guidelines are to design something that:

- prints faster without sacrificing quality,

- increases throughput via clever stacking or layout,

- improves efficiency or reliability through optimisation,

- pushes the limits on overhangs, or

- uses compliant mechanisms in interesting ways.

The response has been very positive so far, and people have already started working on their designs. Seeing the team excited to experiment, share ideas, and improve the shop together has been one of the most rewarding parts of this role.